Experimental Petrology Research in Earth Sciences (EXPRES)

Dr. Laura Waters

EXPRES-Low Temperature Lab (300-1000°C; 25 to 3000 bars) (Dr. Waters; MSEC 135)

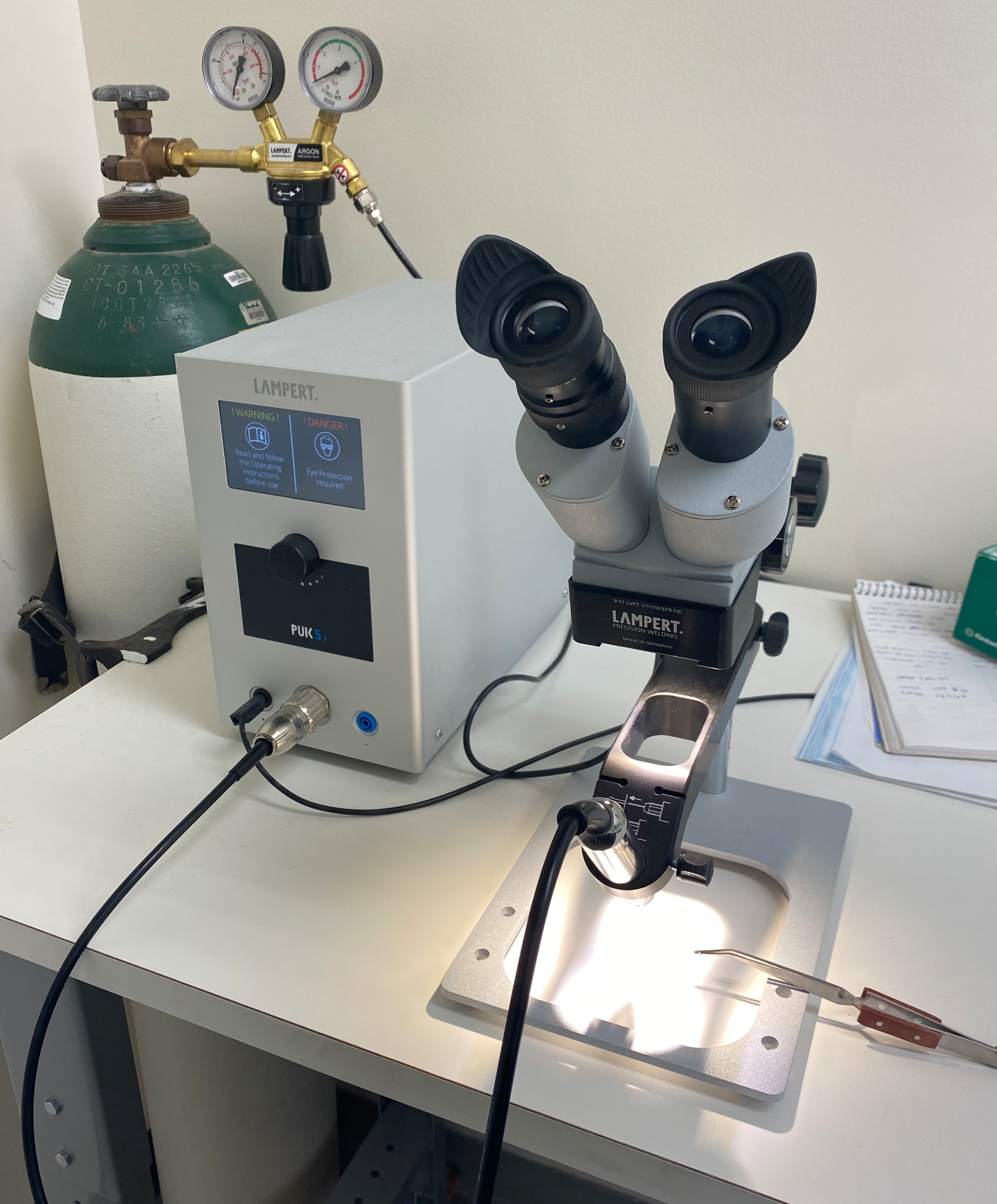

(1) Sample Preparation: The low temperature lab hosts a Lampert PUK, high precision TIG welder for minute

welding tasks like closing experimental capsules. The welder issues precisely controlled

intensities (and durations) of electrical currents through tungsten electrodes in

a stream of Ar-gas. The short bursts of electricity causes locally high temperatures

in the object subject to welding which induces a very localized melt and weld.

(1) Sample Preparation: The low temperature lab hosts a Lampert PUK, high precision TIG welder for minute

welding tasks like closing experimental capsules. The welder issues precisely controlled

intensities (and durations) of electrical currents through tungsten electrodes in

a stream of Ar-gas. The short bursts of electricity causes locally high temperatures

in the object subject to welding which induces a very localized melt and weld.

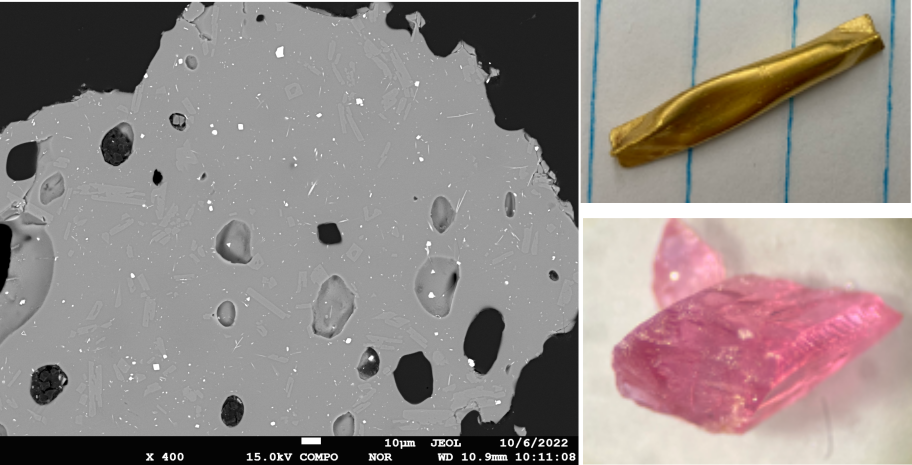

(2) Cold-Seal Pressure Vessel Experimental Apparatus: The low temperature lab is equipped with Waspaloy vessels, pressure heads, pneumatic Haskel pressure intensifier, HiP pressure wheel and fittings, which rest in four Thermo-scientific Linberg Blue Tube Furnaces capable of reaching temperatures ≤1000°C. These vessels simulate temperatures and pressures associated with the upper crust.

Current projects in the EXPRES-Low T lab include: Phase equilibrium experiments for rhyolite melts from Valles Caldera NM, Kinetic experiments targeted at inducing sanidine grown, and experiments targeted at addressing Nd-monazite solubility in aqueous solutions.

EXPRES-High Temperature Lab (800-1550°C; 1 to 15000 bars) (Dr. Waters; MSEC 147)

**Under construction**

The apparatus in this lab were inherited from Dr. Rick Wendlandt, Emeritus Faculty at Colorado School of Mines. The apparatus were transported down from CSM during the midst of the pandemic. Updates to the equipment and electrical infrastructure in MSEC147 have occurred over the past several years.

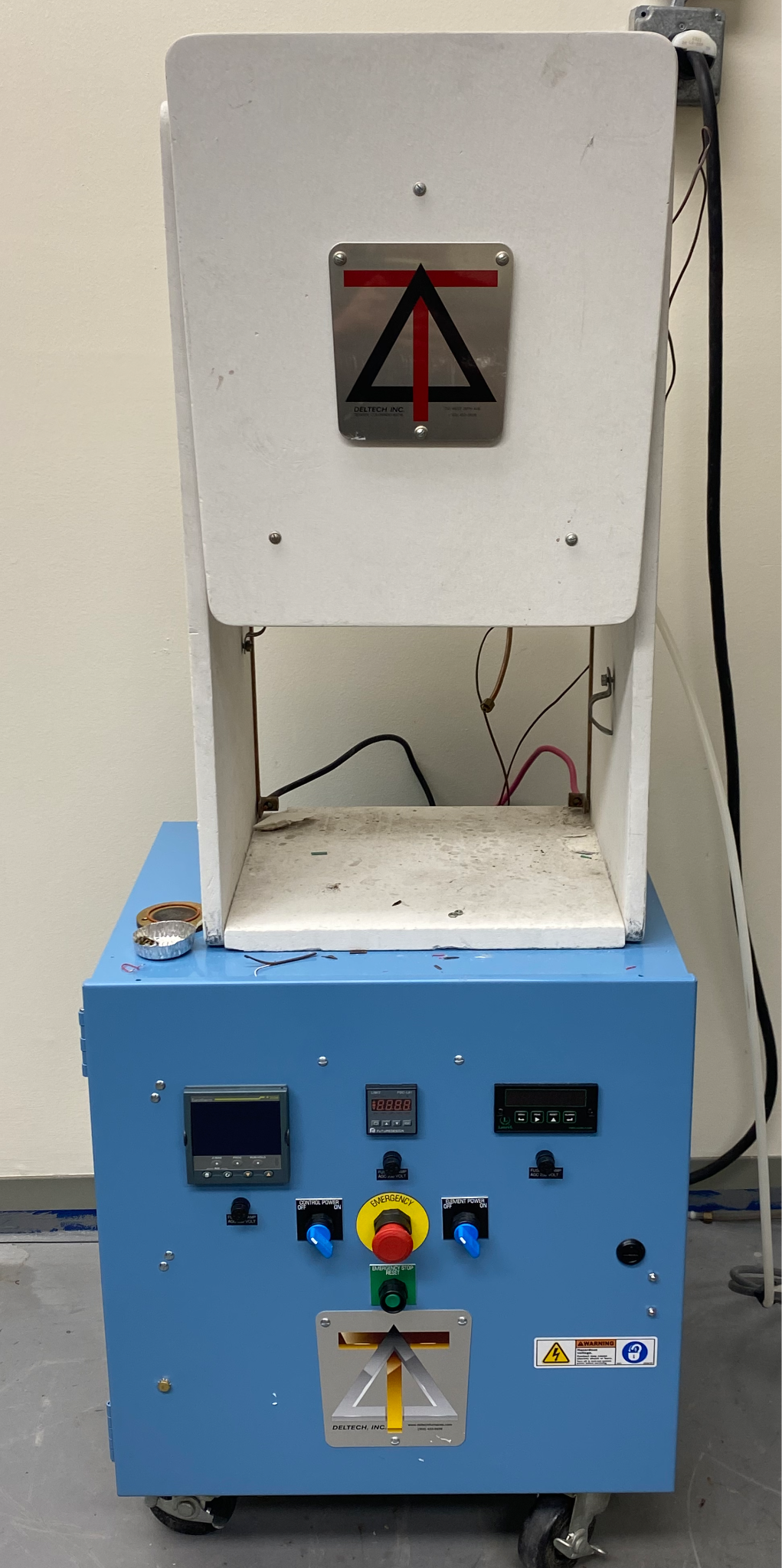

(1) Deltech Gas Mixing furnace:

The gas-mixing furnace is designed so that an internal muffle tube is isolated from

the ambient atmosphere and heated in the core of the furnace. An experiment hangs

in the center of the muffle tube from an Al-ceramic cane on a small precious metal

loop. The partial pressure of oxygen in the atmosphere internal to the muffle tube

is sensed using a zirconia sensor (from Ceramic Oxide Fabricators of Australia) and

controlled using a mixture of carbon monoxide and carbon dioxide. This experimental

apparatus is useful in testing phase equilibria in mafic liquids as a function of

oxygen fugacity, pre-saturating capsule materials to fix the XFe in precious metal

alloys, and determining 1-bar phase equilibria in silicic liquids.

The gas-mixing furnace is designed so that an internal muffle tube is isolated from

the ambient atmosphere and heated in the core of the furnace. An experiment hangs

in the center of the muffle tube from an Al-ceramic cane on a small precious metal

loop. The partial pressure of oxygen in the atmosphere internal to the muffle tube

is sensed using a zirconia sensor (from Ceramic Oxide Fabricators of Australia) and

controlled using a mixture of carbon monoxide and carbon dioxide. This experimental

apparatus is useful in testing phase equilibria in mafic liquids as a function of

oxygen fugacity, pre-saturating capsule materials to fix the XFe in precious metal

alloys, and determining 1-bar phase equilibria in silicic liquids.

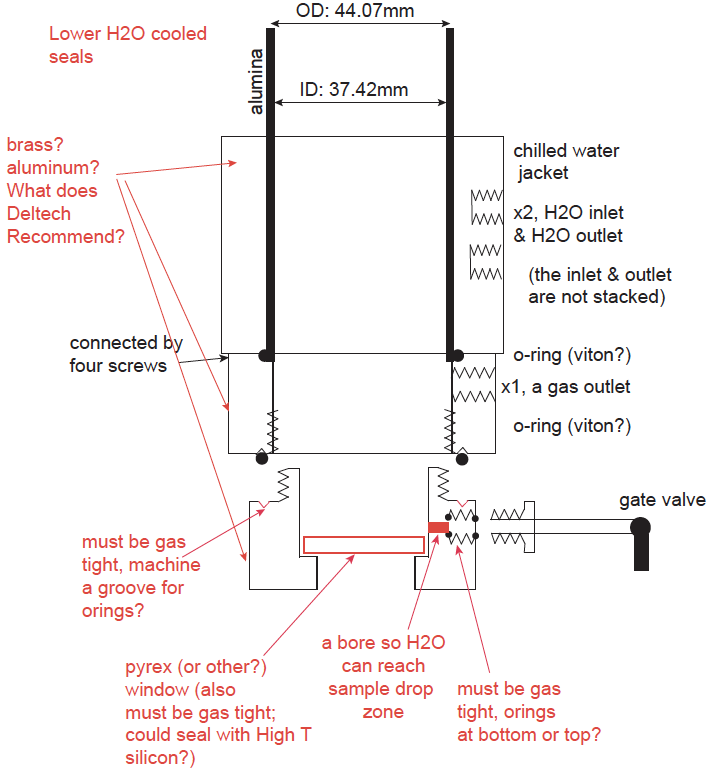

The furnace has been updated with a new controller (in 2022), ammeter and external thermocouple (B-type). New digital AliCat Scientific mass flow controllers have also arrived for precise control of the oxygen fugacity of the atmosphere for the experimental duration. Deltech has also provided the lab with custom cooling jackets for the updated furnace. The lower cooling jacket now includes a port to input a small amount of water prior to quench and a pyrex window to monitor the experiment through its duration and quench. The benefit of the new set up is that the atmosphere can be maintained throughout the entire experiment.

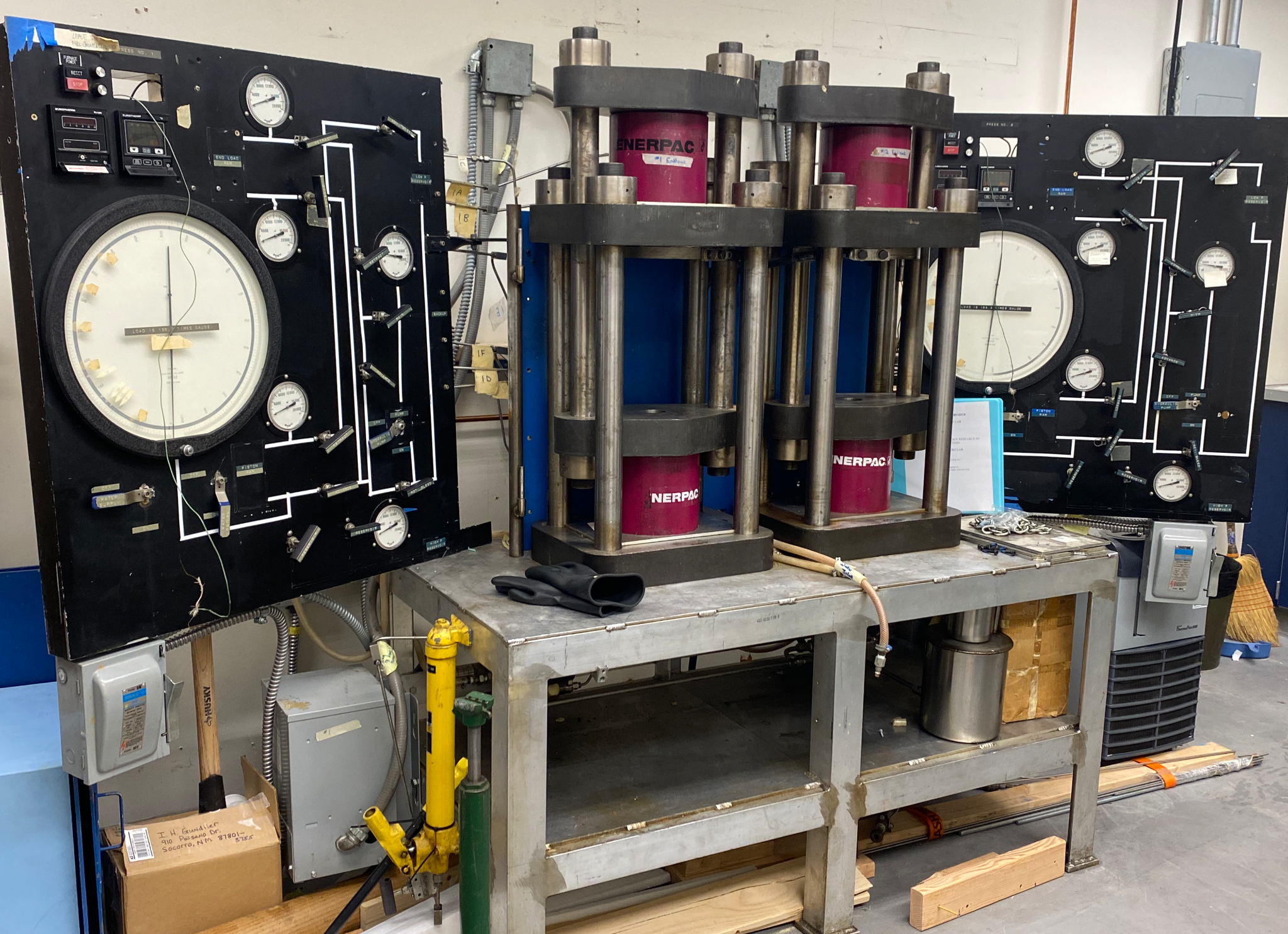

(2) Two Piston Cylinder Apparatus

The piston cylinders originated from JPL and have been moved around the country until they finally found MSEC147. These apparatus are designed to simulate the temperatures and pressures of the lower crust to upper mantle. Two pistons raise an internal frame to compress a stack of cylinders (not shown) and concentrate pressure on a small (0.5” OD) tungsten carbide piston. The sample is heated by electrifying the entire cylinder stack. The pistons come with their own transformer to convert the electricity from the wall to the correct amperage. The temperature and electricity are monitored and corrected by Eurotherm process meters.

These pistons required a significant electrical upgrade to MSEC147 and they will be brought online following completion of the gas mixing furnace set up.